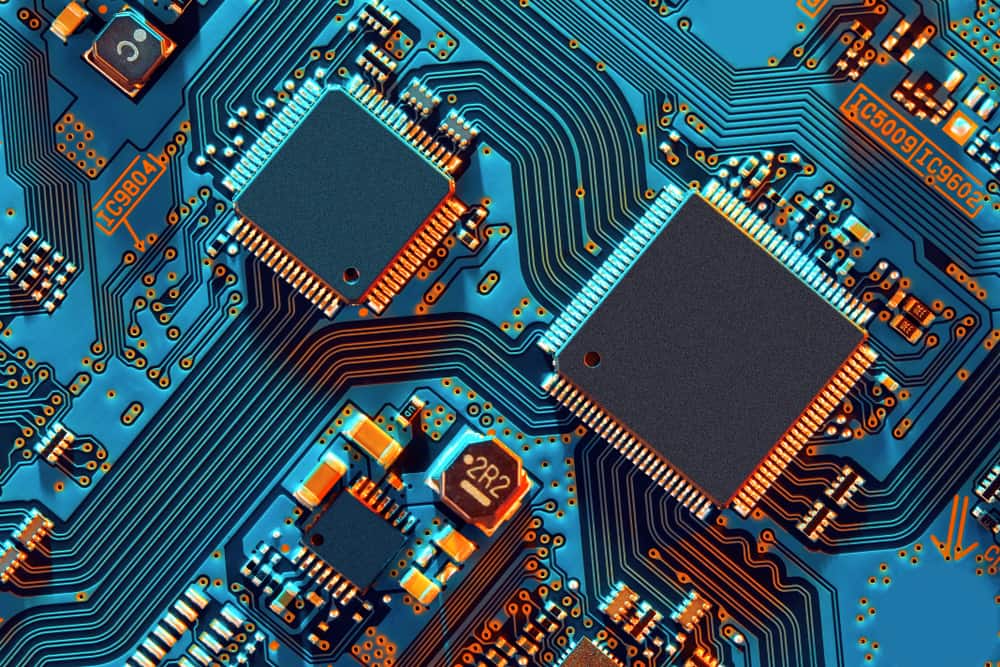

In addition to traces, PCBs will often contain massive copper planes. Then, any unwanted copper is chemically dissolved and washed off leaving only the protected traces. A light-sensitive photoresist coating is applied and cured to protect the desired copper pattern. In order to create the small, elaborate trace patterns needed to function, the copper foil must be chemically etched. Rows of copper, otherwise known as “traces”, form the electrical pathways between components. Furthermore, FR-4 has a level of heat-resistance that protects it during the rigorous high-temperature assembly processes. In addition to physically supporting all the traces and components that will be attached, the FR-4 base insulates the two sides of copper from electrically interfering with each other during operations. Copper foil then covers both sides of the substrate surface. While there are numerous available compounds that can be used to make up this base, the most common is called FR-4. The internal base material or “ substrate” is generally made up of woven fiberglass and resin. The first step puts the literal “board” in “PCB” and forms the groundwork for everything to come. Starting from that foundation, we’ll take you through a basic overview of the PCB fabrication and assembly process, including the following topics: And just like a city, the PCB fabrication process begins with a foundation. Buildings control the major functions of the city from power plants to IT departments. Traffic instructions are posted at every other corner. In fact, there are quite a few parallels between a populated PCB and a bustling metropolis. If you’ve looked closely at a PCB before, you may have noticed the visual similarity it has to a sky view of a city.

Yet for nearly 100 years, the concept of the circuit board has remained the same since the beginning: connect electronic components through a wired surface. Today, PCBs can be mass-produced faster than the eye can follow, and sport components almost smaller than the eye can see. Components could eventually be placed on both the top and bottom of the PCB. Single-layer boards became multi-layer boards. New board printing methods improved efficiency and functionality. Throughout the following decades, PCB designs allowed for more and more complexity within smaller areas. At that time, circuit boards consisted of a sheet of material such as Bakelite or even wood, a wiring layout on one side and components connected through from the other side. Invented to replace the bulky wiring of the early 20 th century, PCB assemblies started becoming commonly used in the late 1940’s, particularly by the U.S. The list is endless.īut what is a PCB? How does it work? What is it made of? They allow you to control your microwave, your car’s dashboard, your X-Box, your lawnmower. In our modern society, PCBs are essential in everyday life, from improving convenience at home to powering business operations to offering endless entertainment.

Today, we’re going to take a brief look at the fundamental item that keeps the electronic world turning: the PCB (meaning “ Printed Circuit Board”).

0 kommentar(er)

0 kommentar(er)